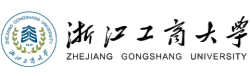

Realize sustainable development through innovation. As the design, construction, and delivery of systems become increasingly complex, OEM manufacturers and suppliers must accelerate innovation, improve efficiency, and create future oriented smart factories to achieve more efficient and agile production. This means that new concepts and methods need to be adopted throughout the entire process of designing, manufacturing, testing, certifying, and maintaining aerospace vehicles.

Design and simulation

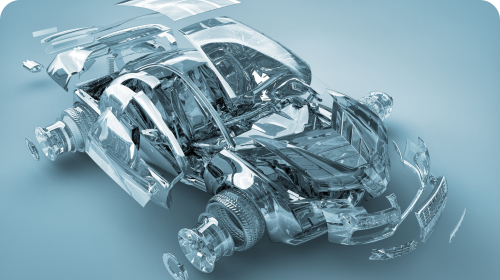

1.Digital modeling and design optimization

Utilize the high-precision 3D modeling capabilities of the 3DEXPERIENCE platform to achieve precise design of complex products such as airplanes and spacecraft. By utilizing functions such as virtual assembly and interference inspection, design issues can be identified in advance to avoid rework during the actual manufacturing process. For example, in the development of a new aircraft model by a well-known aircraft manufacturer, fluid dynamics analysis was conducted using Dassault Systemes software to optimize wing design, reduce flight resistance, and improve fuel efficiency.

2. Multi physics field simulation and performance prediction

Perform multi physics coupling simulation analysis on the aerodynamic performance, structural strength, thermal management, electromagnetic compatibility, and other aspects of aerospace products. For example, in rocket engine design, precise simulations of combustion processes, heat transfer, and fluid flow are conducted to optimize engine performance and reliability; In the design of satellite electronic systems, the integration of schematic design, wiring, and electromagnetic compatibility analysis is achieved to improve the performance of electronic systems.

Manufacturing and process planning

1. Digital manufacturing process planning

A manufacturing solution based on the 3DEXPERIENCE platform enables the design of virtual process planning and manufacturing execution systems, optimizing production processes, improving production efficiency, and reducing costs.

2.Additive manufacturing support

Provide strong support for additive manufacturing in the aerospace industry, including design optimization of 3D printed parts, selection of process parameters, quality control, etc. Help enterprises apply additive manufacturing technology to actual production faster, achieve rapid manufacturing of complex components, and improve production flexibility and response speed.

Supply chain collaboration and management

1.Integrated supply chain platform

Through the Market Place and other functions of the 3DEXPERIENCE platform, knowledge sharing can be achieved to improve efficiency. Suppliers can release design proposals for components, OEMs can find the required parts or assemblies and use them directly, and can also locate suppliers who manufacture components, promoting collaborative cooperation between upstream and downstream enterprises in the supply chain.

2.Supply chain planning and optimization

To solve various challenges in the supply chain of enterprises in the supply, manufacturing, and assembly processes through integrated and end-to-end solutions, optimizing the entire supply chain in different time dimensions of the long, medium, and short term. Enterprises can accurately predict demand based on sales and operational plans, choose the most suitable strategy for the business, and adjust production processes in real-time.

Test and verification

1. Virtual testing and verification

Adopting a brand new industry solution to experience digital verification (TEST TO FORM), connecting all relevant professional content in the testing project process through a single open platform, increasing virtual testing volume, expanding testing scope, deepening testing understanding, and reducing costs. Project managers can use functional digital prototypes to visualize test results in the current environment and make better decisions.

2. Test data management and analysis

Effectively manage and analyze the large amount of data generated during the testing process, generate valuable reports and insights, and provide a basis for product improvement and decision-making for the enterprise. At the same time, ensure traceability of the testing process at all stages and achieve complete management and control capabilities.

Operation and maintenance

1.Virtual operations and training

By utilizing virtual reality (VR) and augmented reality (AR) technologies, virtual operational scenarios and training environments are created to assist employees of airlines and space agencies in conducting efficient training and drills, improving operational skills and emergency response capabilities.

2.Predictive maintenance and health management

By monitoring and analyzing real-time operational data of aerospace products, predicting potential equipment failures and maintenance needs, developing maintenance plans in advance, reducing downtime and repair costs, and improving product reliability and availability.