The automotive industry is driven by efficiency. Manufacturers have been searching for ways to reduce production time and costs while improving vehicle quality and maintainability, and the rise of electric vehicles (EVs) has made competition even more intense. Automotive engineers are walking on thin ice, but with the help of automation, new workflows, and new methods of automotive design, related technologies can still be continuously improved.

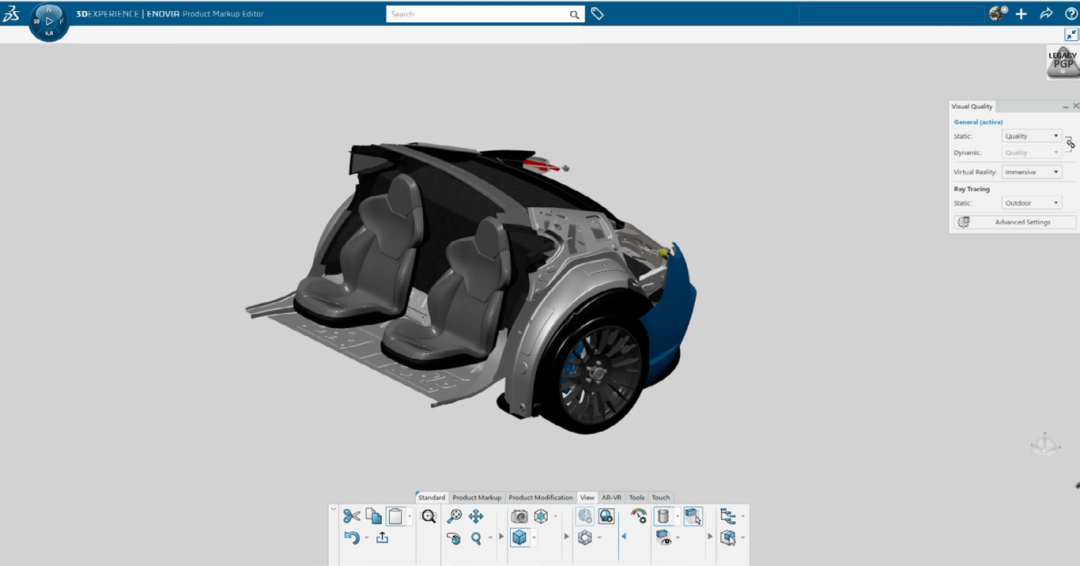

Modular design can help engineers improve manufacturability, maintainability, and maintainability by integrating these factors into a unified approach. Combining product design and simulation with manufacturing simulation can not only shorten production time, but also make automation simpler and more feasible.

What is modular design

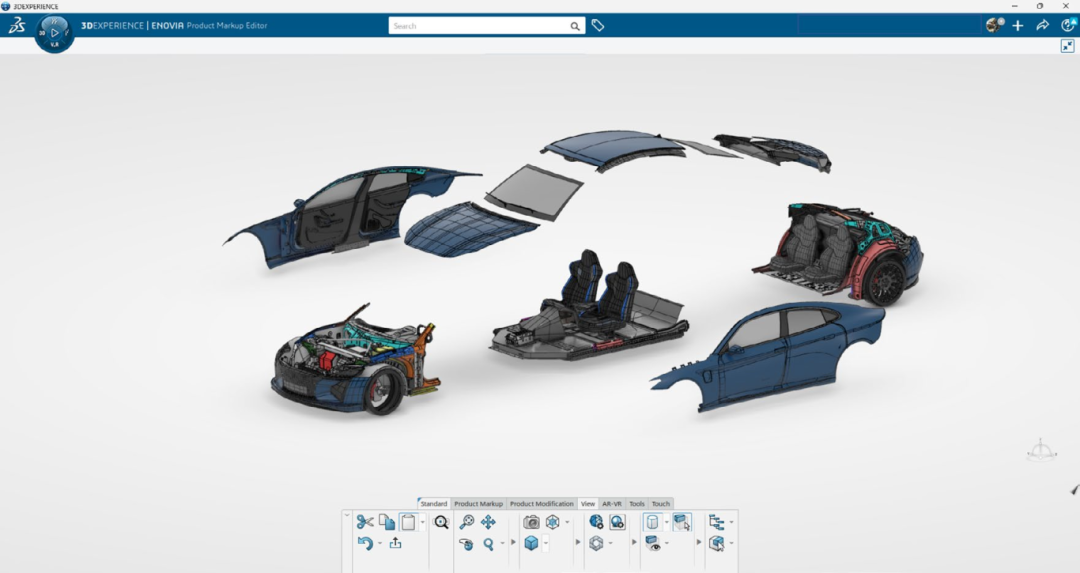

Modular design is the subdivision of a system into "modular" components that can be independently designed, manufactured, tested, and replaced, and in some cases, can also be exchanged with other modules between different systems.

The degree of modularity of a system in terms of dimensions determines its degree of customizability. In a modular system environment, dimensions are just adjustable parameters such as physical shape, production cost, or product lifecycle. Therefore, when it comes to modular design in automotive engineering, the dimensions are very high.

Comparison between Modular Design and Traditional Methods

In a typical automotive design cycle, components are typically tightly integrated into the overall structure of the vehicle. Therefore, it is difficult to make adjustments to the remaining parts of the system simultaneously, and in this case, it is difficult to modify or replace individual parts. Compared to traditional methods, modular design has more advantages:

01

Design freedom: Separate components such as braking and transmission systems that are greatly affected by electrification from components such as information and entertainment systems that may be minimally affected. And after transitioning to electrification, modular design focuses on dividing the system into discrete modules that can be modified or replaced without adjusting the entire system. Such as replaceable battery packs for electric vehicles.

02

Manufacturability: Automakers can be more flexible in their manufacturing strategies, even accommodating multiple vehicle models on a single production line, closer to the concept of Design for Manufacturing (DFM).

03

Sustainability: Standardized components required for modular production support are typically more efficient and take into account recycling issues at the end of their lifecycle, using fewer and more uniform materials to simplify manufacturing and recycling processes.

04

Customization: Automakers can offer a more diverse range of vehicle models, styles, and configurations at sufficiently low development and tooling costs. In an ideal scenario, a fully modular automotive platform only requires minor adjustments to the underlying architecture to support various body styles.

Modular Design of Electric Vehicles

Stimulated by emission regulations and purchase incentives, the electric vehicle market is currently in a period of rapid growth. This growth is driving a consistent demand for automotive platforms that are adaptable to various body styles, highly flexible, and scalable. However, this goal has been hindered by three factors: insufficient battery technology, charging facilities, and component interoperability. Modular design solves these three problems in an interrelated manner:

01

Battery technology: Automotive engineers can create battery systems that upgrade with technological advancements, eliminating the need for car owners to replace the entire vehicle.

02

Charging infrastructure: Electric vehicle manufacturers can design standardized modular battery packs that can be replaced at charging stations. In addition, modular range extenders can also provide auxiliary power for long-distance travel with scarce charging infrastructure.

03

Component interoperability: Automakers can collaborate on standardized electric vehicle components, especially batteries, where drivers can charge the battery pack separately and then combine them when available charging capacity is limited.

The four elements of modular design:

1. Build a cross functional team;

2. Adopt a holistic approach;

3. Keep in mind regulatory requirements;

4. Maintain a unified data source.

Ultimately, adopting a modular design approach in automotive engineering can help overcome the challenges currently faced by the industry when it comes to the popularization of electric vehicles. Whether it is addressing battery technology limitations, available charging infrastructure, or the lack of interoperability between electric vehicles, modular design can help automotive engineers create better electric vehicles, thereby driving the automotive industry in the right direction during this period of change.

As electric vehicles gradually replace internal combustion engine vehicles, the automotive industry is undergoing a transformation. As an automotive engineer, adopting a modular design approach may be challenging, but using the right mindset and starting with the right tools can make the transition smoother.

Source: Dassault Systemes